Lasers

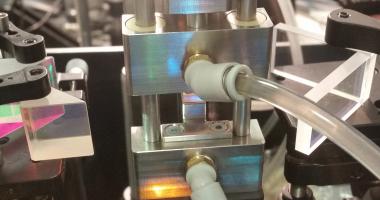

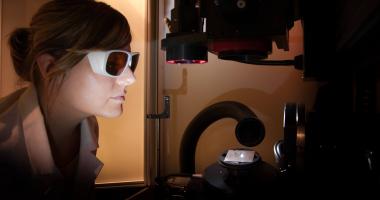

As a specialist in optical and laser processes, ALPhANOV supports the projects of researchers, engineers and industrialists in these fields, thanks to our services and products or through collaborative projects.

Optics and lasers lie at the heart of our business. As a technological centre, ALPhANOV responds to the requirements of scientific research in optics and lasers and to industrialists through a whole range of products and services:

- Development of innovative laser sources

- Development of fibre components

- Laser micro-machining processes

- Laser-piloted electronic cards and modules

- Optomechanical design, optical design and software for photonic systems

This page shows you our activities linked to this field, but do not hesitate to contact us about your projects.

Produits & Services

-

Laser processing

Based on the development of custom-made laser processes for R&D systems, we intervene at every stage of your industrial process. -

Custom Laser Development

Design and development of innovative laser sources based on specialty optical fibers and micro-components in free space. -

Laser Technologies & Components

ALPhANOV commercialises several laser components used inside laser sources: Ps/fs fibre oscillators in OEM version or R&D (with pump to be spliced), integrated medium high-power PCF amplifiers and Kilowatt-class pump combiners. -

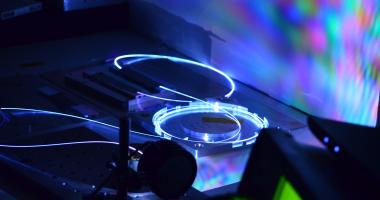

Photonic Crystal Fiber Interfacing

Photonic Crystal Fiber (PCF) gives a real advantage in terms of performance, compactness and reliability. -

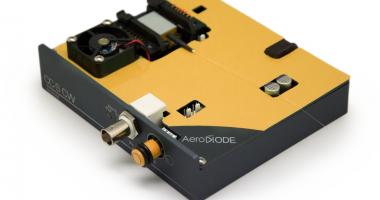

AeroDIODE - Optoelectronics and laser diode drivers

For several years, ALPhANOV has acquired different skills in optoelectronics and has successfully developed a wide range of control modules for optical components. These technologies, which have now reached maturity, were transferred, on January 6, 2020, to the very young company AeroDIODE.

Linked collaborative projects

-

LUMEN Project: Visible-emitting fluoride fiber lasers

The LUMEN project brings together academic and industrial partners with the goal of establishing international leadership in the field of high-power (>2 Watts), continuous-wave fiber lasers emitting in the visible spectrum. It aims to address the...

Learn more -

CRYST^3 - Prototype of a new material based on individual alkali atoms

Developing a new fully-fiber prototype, based on the trapping and cooling of cold atoms in a hollow core fiber.

Learn more -

APACHE - Very high gain and energy lasers at high medium power

Developing a strategic technological brick for laser systems combining very high amplification gains and high energy, compatible with high medium power.

Learn more -

Harmony – Frequency stabilization of lasers using PCF hollow core fibers (HC-PCF)

Develop an all-fiber gas cell component based on PCF hollow core fibers (HC-PCF) that will be used for laser frequency stabilisation.

Learn more -

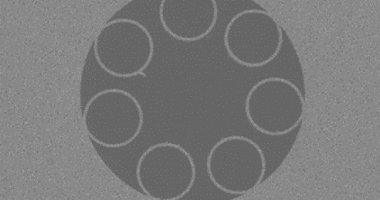

SLALLOM - Holographic microscope

To develop a holographic microscope for all-optical brain studies with a single laser source.

Learn more -

TALSO - New brazing process

Develop a new cold brazing process based on porous silver oxalate joint for the thermal functionalization of optical components.

Learn more -

Convergence - Optical components for power lasers

Design and realize optical components to enable the rise in energy and average power of diode-pumped solid lasers.

Learn more -

DIODE - Platform of expertise and resources based on laser diodes

(2012 - 2015)

To establish a platform of expertise and resources around components, modules and subsystems based on laser diodes.Learn more -

Blue laser - Development of blue fiber lasers

(2008 - 2012)

To develop a new family of high-power blue fiber lasers.Learn more

Publications

- Investigating the glass structure of Yb3+/Al3+/P5+ doped silica preforms prepared by suspension method, N. Tiabi, R. Dauliat, J.L. Auguste, S. Vergnole, P. Florian, A. Canizares, J.R. Duclere, K. Wondraczek, & P. Roy - 2023

- 55 µm core ytterbium-free erbium-doped VLMA fiber manufactured by REPUSIL technology, B. Leconte et al., - 2024

- Self-referenced multiplex CARS imaging with picosecond pulse generated supercontinuum by using second and third order nonlinearities, S. Wehbi, T. Mansuryan, M. Fabert, A. Tonello, K. Krupa, S. Wabnitz, S. Vergnole, V. Couderc

- Continuous spatial self-cleaning in GRIN multimode fiber for self-referenced multiplex CARS imaging, S. Wehbi, T. Mansuryan, K. Krupa, M. Fabert, A. Tonello, M. Zitelli, M. Ferraro, F. Mangini, Y. Sun, S. Vergnole, H. Kano, S. Wabnitz, V. Couderc - 2022

- Record power transmission of intense UV radiation in a single-mode hollow-core fiber with 23.3W, 155μJ, 10ns pulses at 343nm, F. Leroi, A. Guillossou, J. Didierjean, J. Saby, J. Boullet - 2022

- Pushing laser nano-structuring through mass production, G. Mincuzzi, A. Bourtereau, A. Sikora, M. Faucon, R. Kling

- 200W electro-optic frequency comb from a monolithic fiber laser with tunable repetition rate between 1 and 18 GHz featuring 200 fs pulses, F. Leroi, H. Ye, G. Santarelli, J. Boullet, E. Cormier

- LIPSS and DLIP: From hierarchical to mutually interacting, homogeneous, structuring, A. Sikora, M. Faucon, L. Gemini, R. Kling, G. Mincuzzi - 2022

- High-power nonlinear amplification of an ultrafast electro-optic frequency comb with flexible GHz repetition rate, H. Ye, F. Leroi, L. Pontagnier, G. Santarelli, J. Boullet, E. Cormier - 2022

- Electro-optic comb pumped optical parametric oscillator with flexible repetition rate at GHz level, H. Ye, V. Freysz, R. Bello-Doua, L. Pontagnier, G. Santarelli, E. Cormier, E. Freysz

- Intra-volume processing of gelatine hydrogel by femtosecond laser-induced cavitation, I. Vérit, L. Gemini, J.C Fricain, R. Kling, C. Rigothier

- Role of the intensity profile in femtosecond laser surface texturing: An experimental study, A. Sikora, S. Nourry, M. Faucon, B. Chassagne, R. Kling, G. Mincuzzi

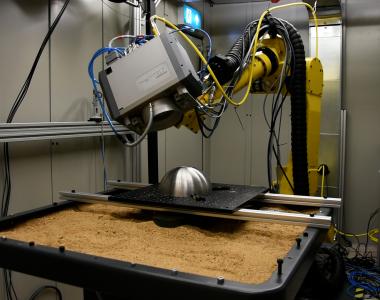

- Mid-infrared hollow core fiber drawn from a 3D printed chalcogenide glass preform, J. Carcreff, F. Cheviré, E. Galdo, R. Lebullenger, A. Gautier, J.L Adam, D. Le Coq, L. Brilland, R. Chahal, G. Renversez, J. Troles

- High power continuous laser at 461 nm based on a compact and high-efficiency frequency-doubling linear cavity, C.-H. Feng, S. Vidal, P. Robert, P. Bouyer, B. Desruelle, M. Prevedelli, J. Boullet, G. Santarelli, A. Bertoldi

- Electro-optic comb pumped optical parametric oscillator with flexible repetition rate at GHz level, H. Ye, V. Freysz, R. Bello-Doua, L. Pontagnier, G. Santarelli, E. Cormier, E. Freysz

- Scalable amplification with a high gain x energy product at room temperature using a thick slab of Yb3+:YAG, A. Jolly, J. Boullet, G. Machinet

- 30 TW and 33 fs pulses delivered by a Ti:Sa amplifier system seeded with a frequency-doubled fiber laser, S. Boivinet, A. Pellegrina, L. Ranc, T. Morbieu, S. Vidal, J.-P. Yehouessi, P. Morin, H. Lecommandoux, K. Robin, C. Vinçont, C. Pierre, M. Berisse

- High gain amplification up to 100 mJ to 3 J using Yb3+:YAG slab-based cat’s-eye cavities under variable seed and operating conditions, A. Jolly, G. Machinet, and J. Boullet

- Nonlinear imaging using a 35 fs 3.5 nJ all-PM fiber laser frequency doubled at 800 nm, C.-H. Hage, S. Boivinet, S. Vidal, G. Machinet, J. Boullet

- 178 fs, 1.2 nJ pulses from an all-polarization maintaining fiber figure 8 laser based on 3 × 3 coupler at 1 μm, S. Boivinet; S. Vidal; J. Boullet

- Ultra-high brightness, low insertion loss, kW-class co and contra propagative 6+1:1 combiner, Y-V Bardin; C. Pierre; J. Boullet

- Thermal lensing effects in rod-based Tm3+: YLF amplifiers versus pump and cooling conditions, A Jolly; S Vidal; J Boullet

- 3 W Mid-IR supercontinuum extended up to 4.6 µm based on an all-PM thulium doped fiber gain-switch laser seeding an InF3 fiber, J-P. Yehouessi; S. Vidal; J-Y. Carrée; L. Bodin; S. Cozic; T. Berthelot; S. Poulain; L. Calvez; G. Huss; J. Boullet