Our current collaborative projects

-

Femtocell: A pilot line for next-generation (Gen4) batteries

The Femtocell project brings together leading industrial and technological partners around a shared goal: to develop a femtosecond laser pilot line dedicated to the cutting and structuring of electrodes for next-generation batteries. It addresses the...

Learn more -

LUMEN Project: Visible-emitting fluoride fiber lasers

The LUMEN project brings together academic and industrial partners with the goal of establishing international leadership in the field of high-power (>2 Watts), continuous-wave fiber lasers emitting in the visible spectrum. It aims to address the...

Learn more -

HURRICANE European Project

Enhancing disaster response efficiency and safety for first responders during natural disaster.

Learn more -

The Gemini project: Study of perovskite degradation

An exceptional collaboration between the Laboratoire de Réactivité et Chimie des Solides and ALPhANOV for applications in renewable energies and the development of innovative, sustainable materials.

Learn more -

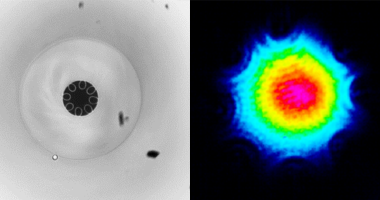

XPulse² - Innovative laser-generated X-ray medical imaging system

Breast cancer is the most common cancer among women worldwide: almost 1 in 8 will be affected. It is therefore essential to constantly work on innovative technologies to improve screening and diagnosis at early stages. This is the aim of the XPulse...

Learn more -

BioFibreLoop - Pioneering sustainable clothing

Manufacturing of circular biobased technical textiles with innovative, bio-inspired, laser induced functionalization

Learn more -

FASS - Fast and Accurate Solubility for Sustainability

Bring to the market a revolutionary laboratory instrument for the measurement of the solubility of drug molecules.

Learn more -

Q-CELL - Quantum CELL

Proof-of-concept for a compact, fully fibered rubidium vapor cell.

Learn more -

CALICE - All-in-one handheld sensor for measuring key vineyard parameters

Development of an all-in-one handheld sensor providing comprehensive evaluation of the technological and phenolic potential of grapes in a vineyard plot.

Learn more -

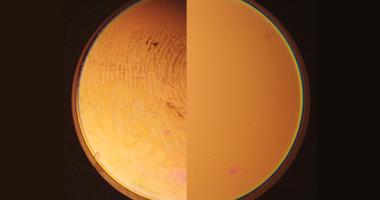

R&T CNES : hybrid surface functionalization process

In the context of a collaborative project with CNES (R&T challenge), ALPhANOV aims to develop a hybrid adhesion process for the creation of optical assemblies for space applications.

Learn more -

PhOENIX - Photonics - Intelligent and Proven Digital Educational Tools

Developing digital tools for photonics training.

Learn more -

Nouvelle-Aquitaine Photonics TALENT

The Photonics TALENT project is designed to meet the challenges of recruitment and skills development in this fast-growing industry of the future.

Learn more