Surface engineering

Laser surface engineering or functionalization enables the creation of effects or the addition of new properties to all types of surfaces and materials, depending on the desired function.

ALPhANOV draws inspiration from nature to develop laser processing capable of modifying material surfaces. Whether metals, ceramic, or glass, their properties can now be enhanced through surface functionalization. Applications are numerous and span multiple markets, including superhydrophobicity, superhydrophilicity, antibacterial properties, antifouling, emissivity modification, and anti-reflective effects.

These functionalities can be applied to both transparent materials and metals, including small components such as turned parts.

For each material, a wide range of laser treatments is available, each providing precise functionalities and effects tailored to your specific needs.

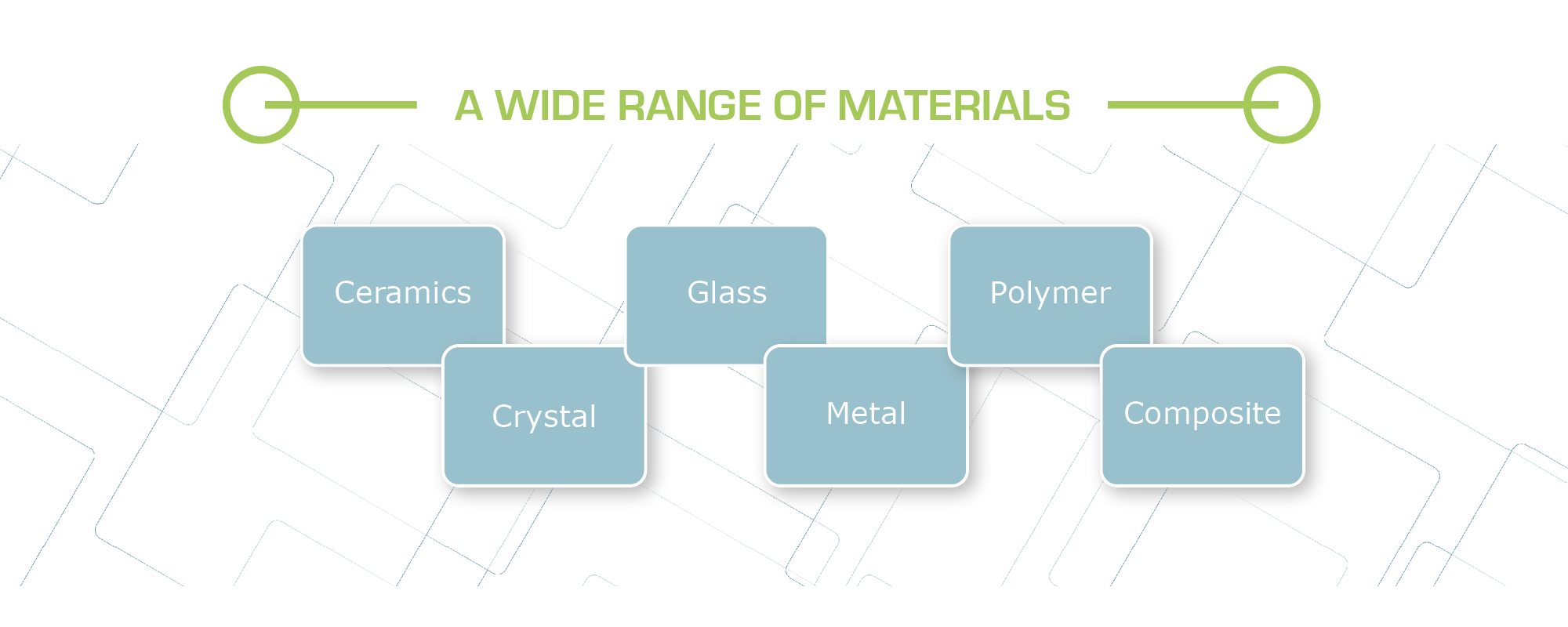

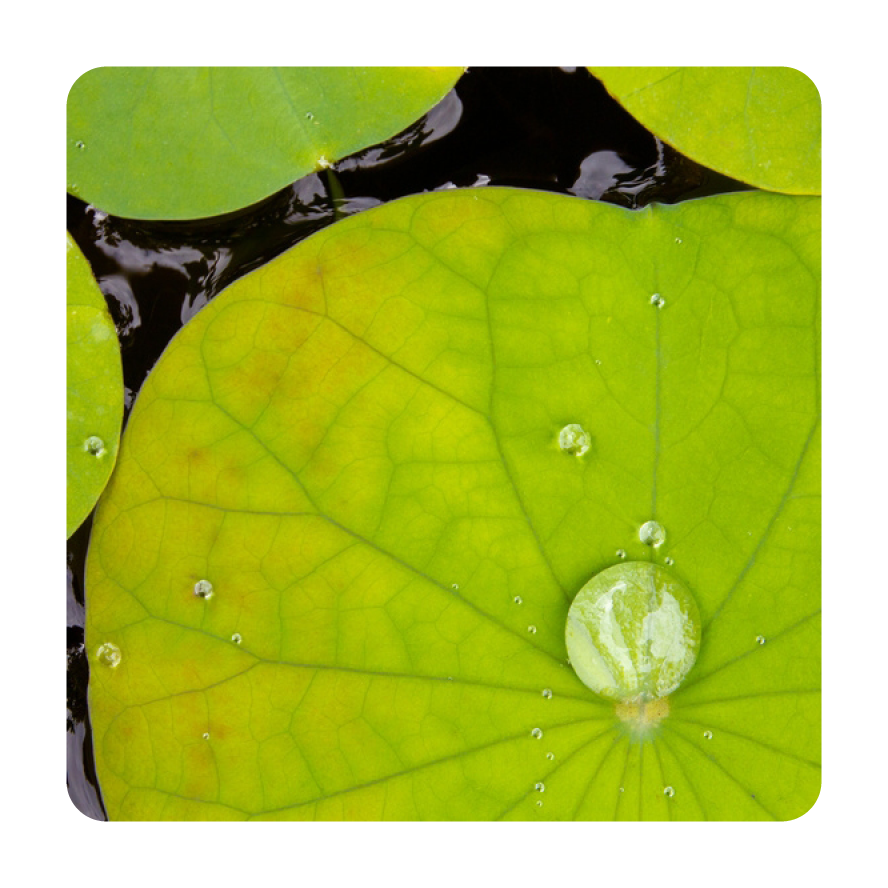

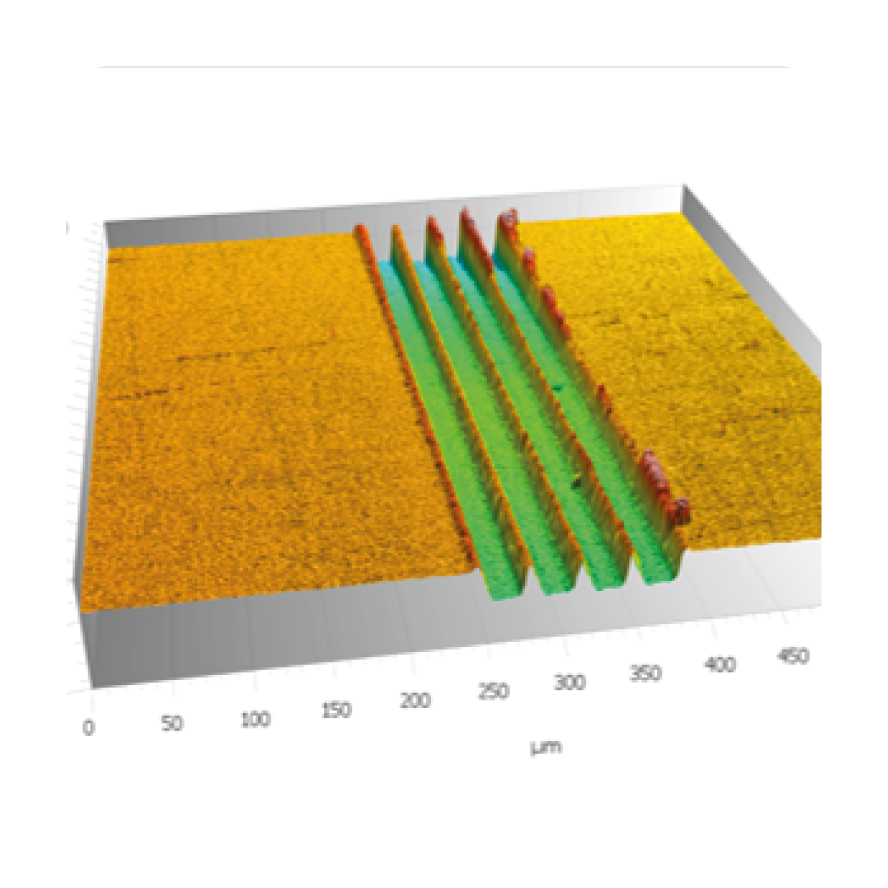

Modification of wettability

Lotus leaf effect - Hydrophobic surface

|

|

|

|||

|

|

|

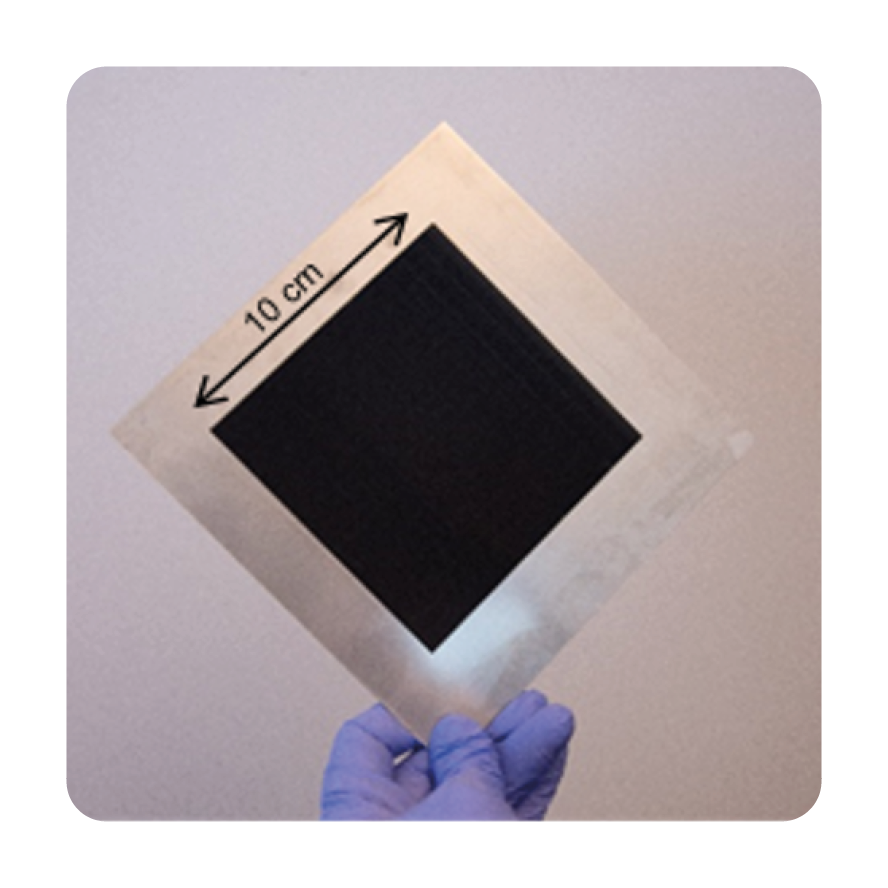

Emissivity reduction

Light trapping effect - Butterfly eye

|

|

|

|||

|

|

|

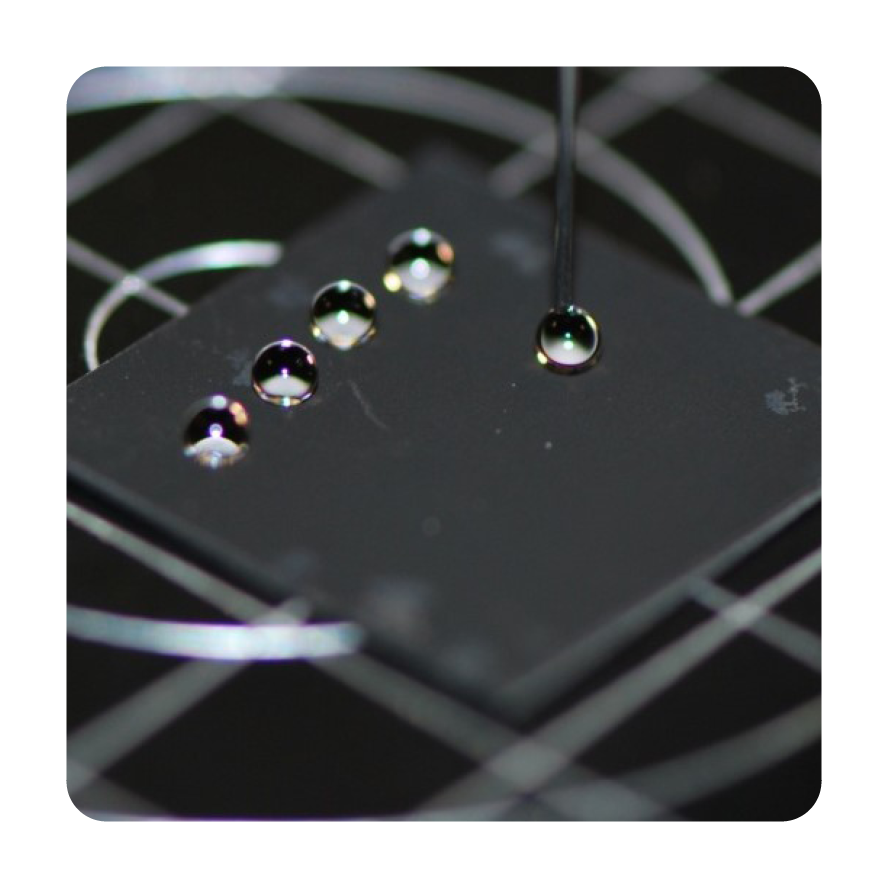

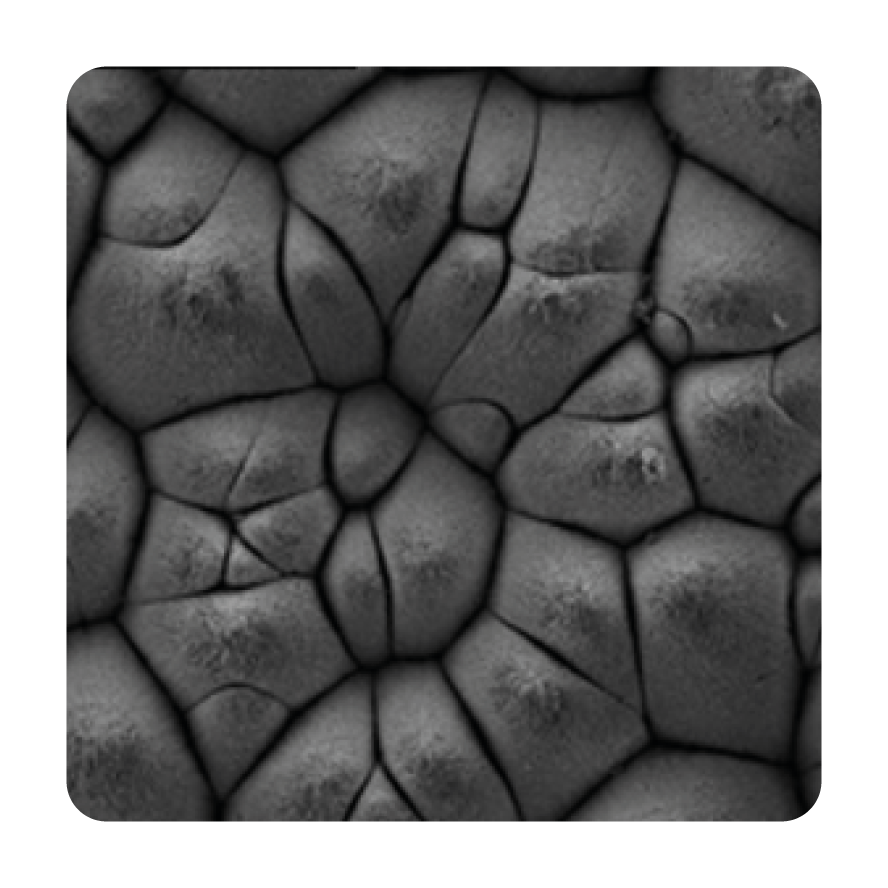

Drag reduction and anti-fouling

Friction reduction - Shark skin effect

|

|

|

|||

|

|

|

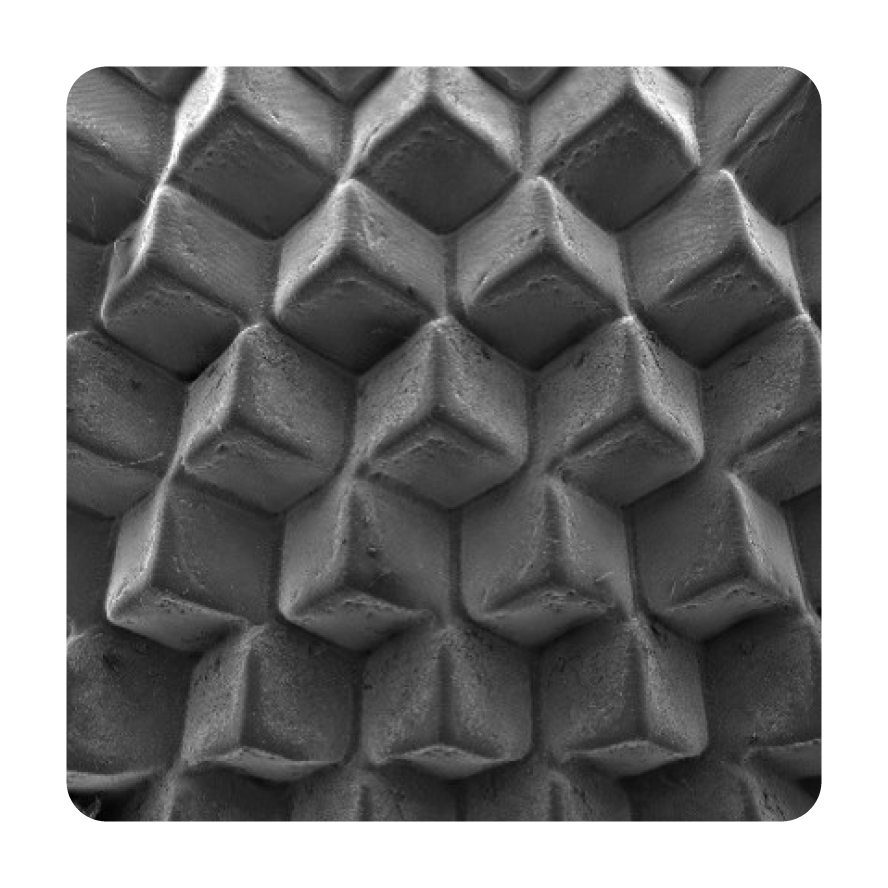

Decoration and materials remodeling

Iridescence - Beetle shell

|

|

|

|||

|

|

|

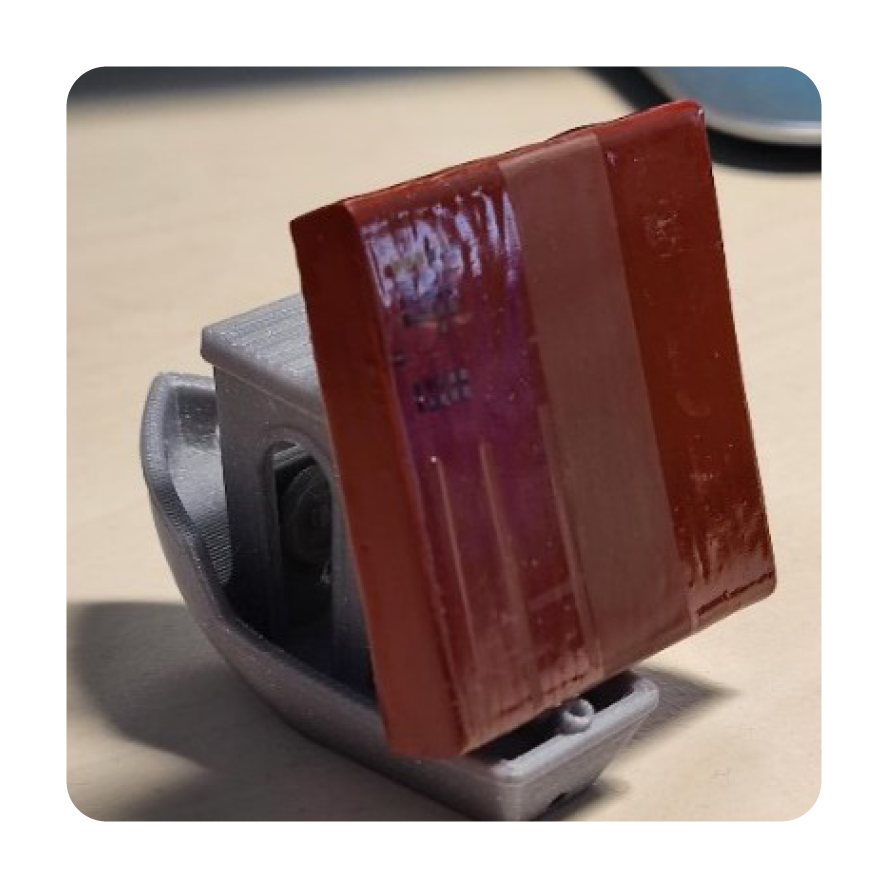

Today, these processing can be directly implemented in industrial environments with the support of experts such as ALPhANOV. Prototypes and systems incorporating inline metrology are now comercially available.

Process sheet

Areas of application

- Sensors

- Aeronautics

- Medical

- Household appliances

- Food packaging

- Energy

Publications

- Role of the intensity profile in femtosecond laser surface texturing: An experimental study, A. Sikora, S. Nourry, M. Faucon, B. Chassagne, R. Kling, G. Mincuzzi

- Single and dual wavelength double fs-pulse laser irradiation for transparent material processing, J. Lopez, K. Gaudfrin, K. Mishchik, M. Delaigue, C. Hönninger, E. Audouard, R. Kling, G. Duchateau

- Square top-hat and round top-hat laser beam shaping with multi-plane light conversion for femtosecond laser material microprocessing, C. Jacquard, G. Mincuzzi, M. Faucon, A. Sikora, R. Kling, G. Pallier, N. Laurenchet, P. Jian, O. Pinel, G. Labroille

- Short and long term surface chemistry and wetting behaviour of stainless steel with 1D and 2D periodic structures induced by bursts of femtosecond laser pulses, G. Giannuzzia, C. Gaudiuso, R. Di Mundo, L. Mirenghi, F. Fraggelakis, R. Kling

- Double- and Multi-Femtosecond Pulses Produced by Birefringent Crystals for the Generation of 2D Laser-Induced Structures on a Stainless Steel Surface, F. Fraggelakis, G. Giannuzzi, C. Gaudiuso, I. Manek-Hönninger, G. Mincuzzi, A. Ancona, R. Kling

- Controlling 2D laser nano structuring over large area with double femtosecond pulses, F. Fraggelakis, G. Mincuzzi, J. Lopez, I. Manek-Hönninger, R. Kling

- Springtail-inspired triangular laser-induced surface textures on metals using MHz ultrashort pulses, J.-M. Romano, R. Helbig, F. Fraggelakis, A. Garcia-Giron, C. Werner, R. Kling, S. Dimov - 2019

- Towards Laser-Textured Antibacterial Surfaces, A. H. A. Lutey, L. Gemini, L. Romoli, G. Lazzini, F. Fuso, M. Faucon & R. Kling - 2018

Associated products or services

-

Laser machining and micro-machining

Laser machining or laser micro-machining enables the production of very high-precision parts, with micrometer-scale tolerances. It is used for cutting, drilling, controlled engraving, selective ablation, and micro-turning operations. -

Machining of transparent materials

Cutting, welding, drilling and engraving of transparent materials with minimization of mechanical stress. Short or ultra-short pulse lasers allow transparent materials to be machined with or without removal of material and to modify their intra-volume physical properties.