Our Technological platforms

From component to system — and all the way to laser processing implementation, ALPhANOV places its expertise at the service of industry and research, supporting partners from component design to full system integration and laser process implementation.

Our support enables them to bring new technological developments to maturity across key markets and challenges in Aerospace, Defense, Health, Industry 4.0, and Sustainable Development.

A Powerful Technological Arsenal

Over nearly 20 years of existence, ALPhANOV has developed unique know-how and built an exceptional technological foundation covering the entire photonics value chain.

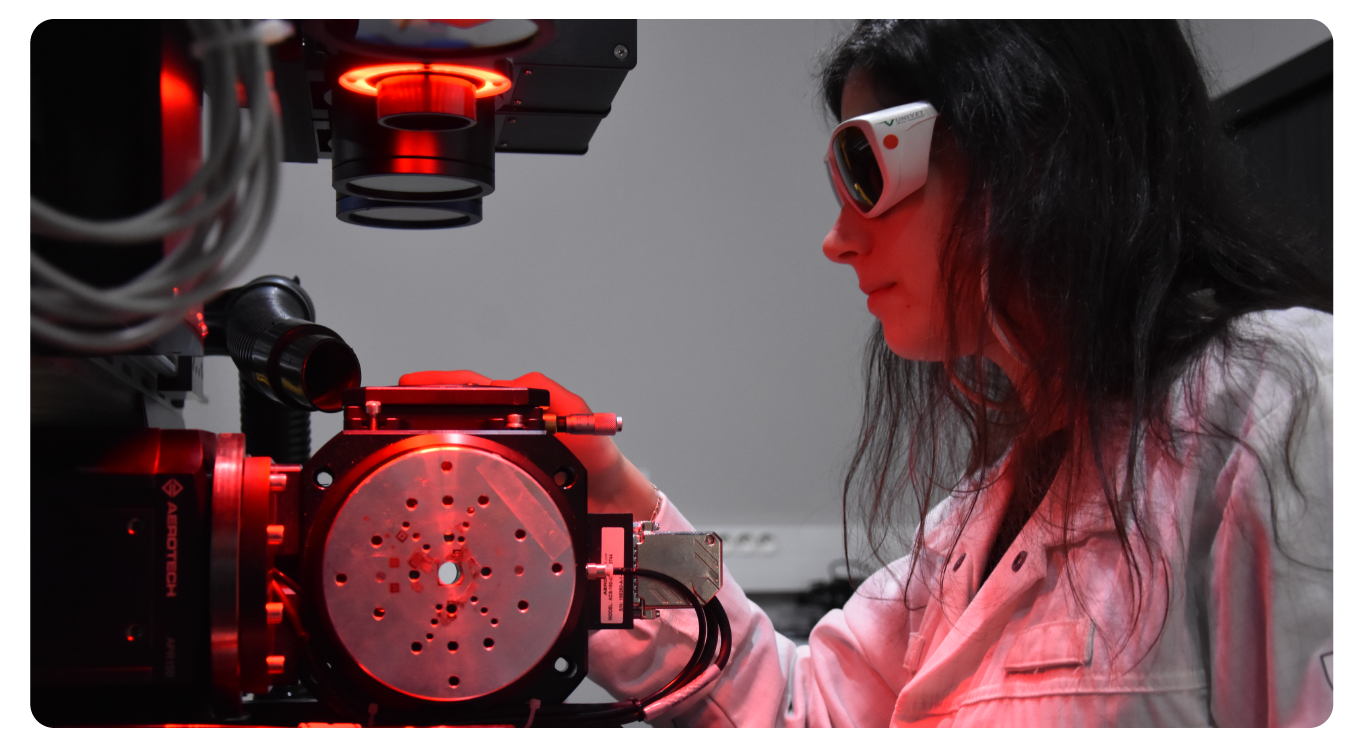

Laser Processing Platform

To support research and innovation, the center is equipped with an outstanding laser park — unique in France.

This collection includes lasers with pulse durations ranging from femtoseconds (athermal processes with micrometric resolution) to continuous wave operation (thermal processes with very high material removal rates), and wavelengths spanning from the ultraviolet (notably for polymer processing) to the infrared.

Complementary equipment includes 5-axis laser machining stations, laser turning systems, ultra-fast beam deflection heads, cutting and drilling systems, and 6-axis robotic platforms.

Metrology Platform

To ensure the quality and reproducibility of our developments, we rely on a state-of-the-art metrology platform.

Complementing our machining activities, this platform is equipped with multiple 2D and 3D dimensional inspection systems, roughness and wettability measurement tools, a scanning electron microscope (SEM), and an atomic force microscope (AFM).

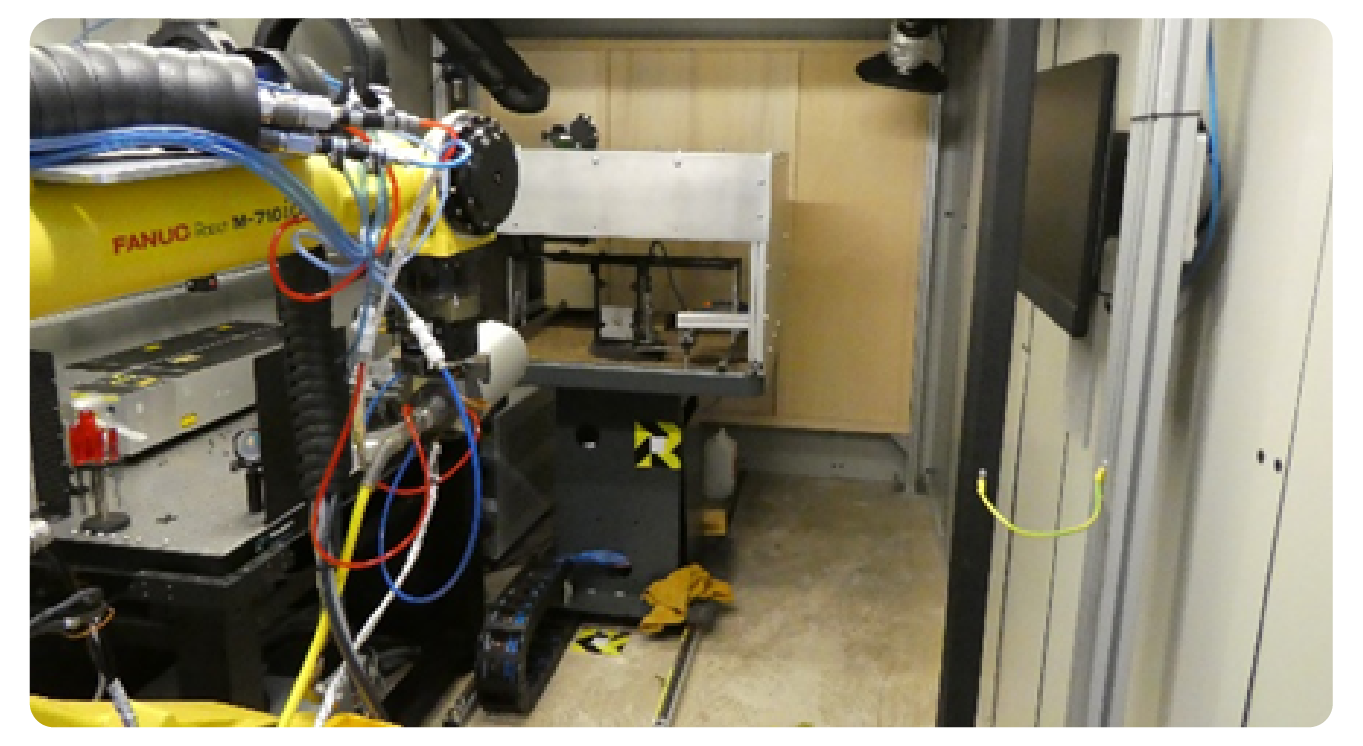

Laser Vulnerability Testing Platform

Since 2019, ALPhANOV has operated a secure laboratory dedicated to studying laser–matter interactions under high-intensity conditions.

It features a 10 kW CW laser source, combined with multiple beam-shaping systems (top-hat, scanner) mountable on a FANUC robot. The laboratory also includes a wide range of diagnostic tools, such as high-speed imaging (visible and infrared), pyrometers, and thermocouples.

This facility is fully reconfigurable to meet the specific requirements of our clients and partners.

Environmental Qualification Platform

ALPhANOV conducts environmental testing (vibration resistance, thermal cycling), particularly on optoelectronic devices such as laser diodes and associated driver electronics.

Our equipment also enables the pre-qualification of prototypes or proof-of-concept systems intended for harsh environments.

To ensure optimal reliability, these tests can be complemented by partner-led assessments under salt fog, sand, hail, mold, or contaminant fluid exposure.

Special Optical Fiber Functionalization Platform — “SOFIA(*)”

(*) SOFIA : Specialty Optical Fiber Interfacing & Assembly

This platform includes a wide range of standard and custom cleavers and splicers suited for micro-structured fibers, ALPhANOV-designed polishers, and advanced characterization tools.

Operated by ALPhANOV for the production of photonic crystal fiber assemblies and advanced functionalizations, it is also accessible to industrial and academic partners for the development of laser sources and related components.

RESANOV Platform

For nearly 10 years, ALPhANOV has offered access to a set of around twenty optical, mechanical, and electronic instrumentation systems for members of the ALPHA-RLH competitiveness cluster.

These instruments are available either with technical assistance or for autonomous use by trained operators.