Femtocell: A pilot line for next-generation (Gen4) batteries

The Femtocell project brings together leading industrial and technological partners around a shared goal: to develop a femtosecond laser pilot line dedicated to the cutting and structuring of electrodes for next-generation batteries. It addresses the challenges of modernizing battery production lines with more sustainable and precise processes, while strengthening European technological sovereignty and France's leadership in ultrafast laser technology.

Towards cleaner and higher-performance battery production

The energy transition and the rapid rise of electromobility are driving a fast evolution in energy storage technologies. In response, industry players are working to modernize their production lines with a new generation of batteries that are more precise, efficient, and faster to manufacture.

These transformations align with a broader European strategic ambition: to strengthen the continent's technological sovereignty while consolidating France's leadership in ultrafast laser innovation, with a strong regional impact on the innovation ecosystem.

Within this context, the Femtocell project aims to develop a pilot line based on a high-power femtosecond laser source (400 W, GHz repetition rate) dedicated to the cutting and structuring of electrodes for next-generation (Gen 4) batteries, where the traditional liquid electrolyte is replaced by a polymeric or even solid material, significantly improving performance.

Ultrafast laser technology serving Gen4 batteries

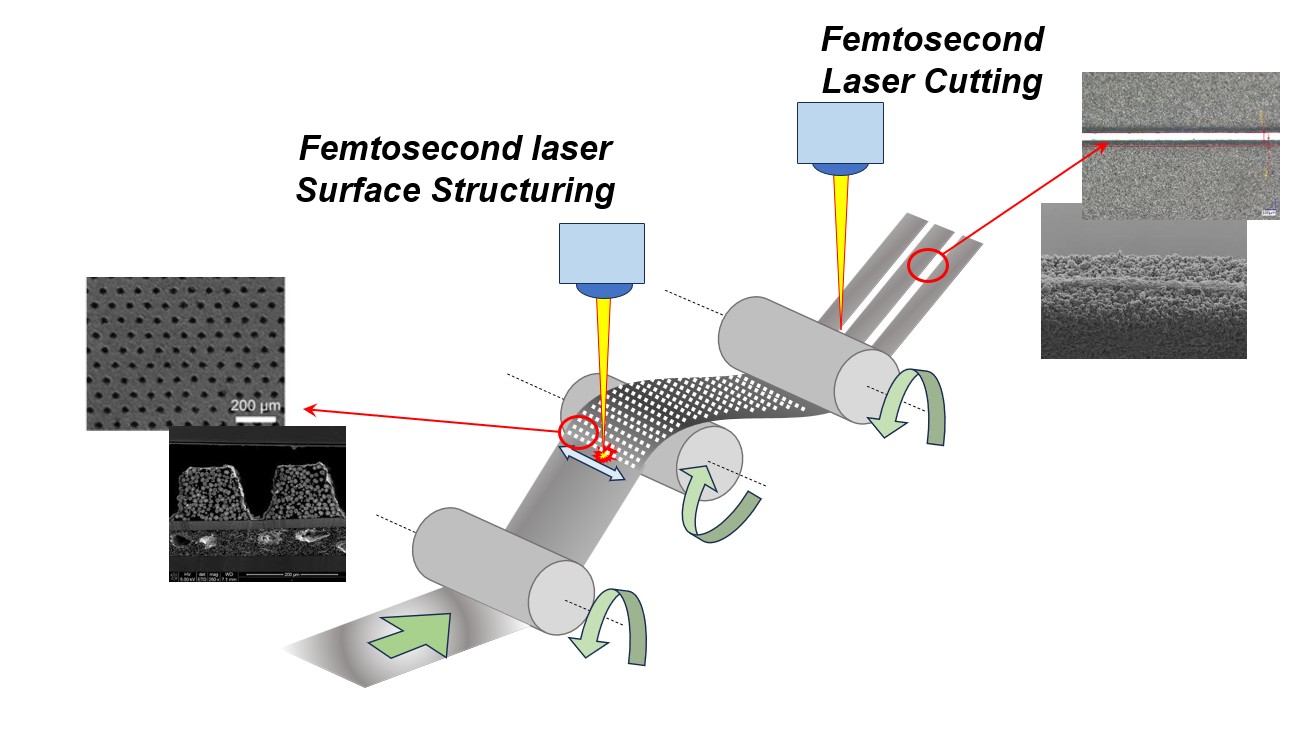

Concretely, the Femtocell project focuses on developing a 400 W ultrafast (fs) laser operating at GHz frequencies, specifically designed for cutting and texturing electrodes used in next-generation batteries. The use of these innovative, high-repetition-rate laser sources enables greater efficiency while ensuring optimal processing quality.

The laser beam will be split into multiple sub-beams to fully utilize the available power and increase production throughput. This system will be integrated into a roll-to-roll machine, capable of processing 12cm-wide electrodes at speeds compatible with industrial standards.

|

Led by Amplitude, the project brings together leading industrial and technological partners (Cailabs, Groupe Huguet, Saft), covering the entire value chain, from laser development to battery manufacturing and characterization. By combining these complementary areas of expertise, Femtocell contributes to raising the technological readiness level (TRL) of these processes and preparing their integration into real industrial environments.  |

ALPhANOV's role

As a project partner, ALPhANOV contributes its expertise in laser process control applied to battery manufacturing, particularly in the cutting and structuring of electrodes, including the definition of patterns and the development of optical systems required for the implementation of the pilot line.

Beyond its technical contribution, Femtocell illustrates the wide range of application domains that photonics can address, from the industry 4.0, through the deployment of innovative and sustainable processes, to sustainable development, by improving energy efficiency and reducing the environmental impact of manufacturing operations.

The know-how developed within the European project GigaGreen, which focuses on eliminating hazardous solvents in favor of water-based solutions, will be leveraged in Femtocell.

While GigaGreen targeted processes at a lower technological maturity level (TRL), Femtocell takes the next step by advancing toward higher TRLs, aiming for large-scale industrial implementation.

Funders:

This project has been funded by the French government under the France 2030 program.

Duration : 48 months