Transparent materials

Laser micromachining of transparent materials opens new perspectives for modifying physical properties and functionalizing materials, either on the surface or in depth, with or without material removal.

For more than 15 years, ALPhANOV has been developing unique expertise in laser processing, combined with advanced beam-shaping techniques for the processing of transparent materials, particularly for applications in optics and microfluiduics.

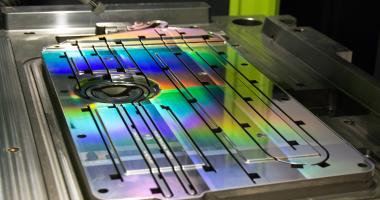

Laser processing has revolutionized the machining of transparent materials. Quartz, transparent ceramics, soda-lime glass, and borosilicate glass offer a wide range of possibilities. In addition, surface engineering enables controlled modifications of optical reflection, including the creation of anti-reflective effects.

Each process is characterized by its own unique properties.

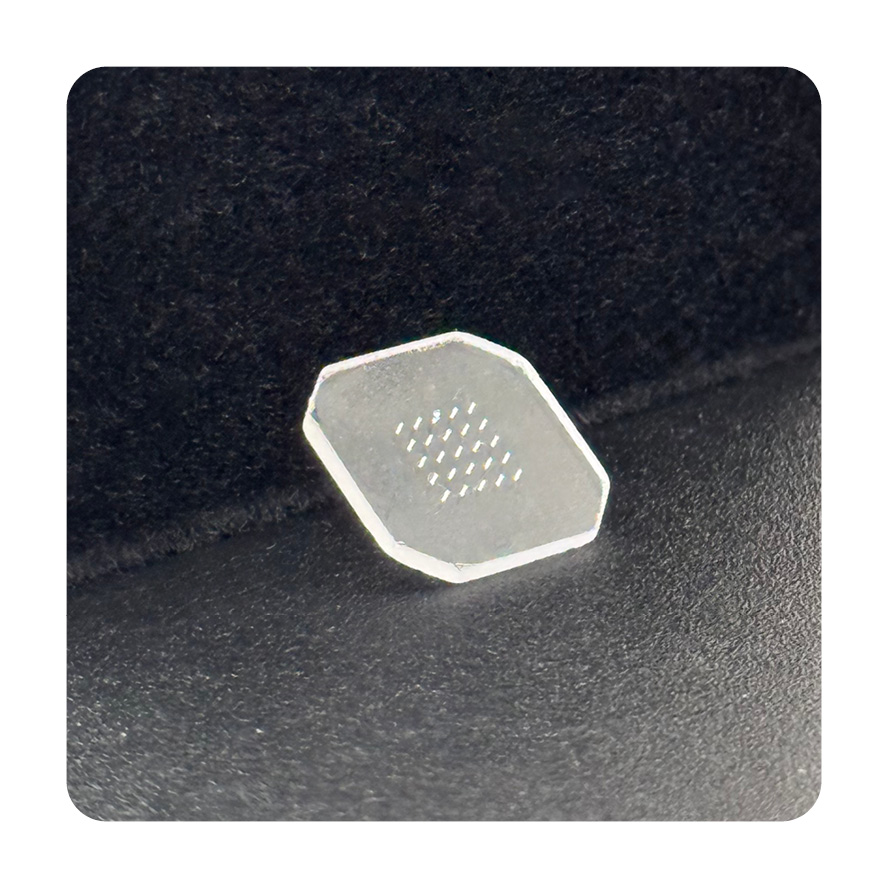

Cutting and drilling

-

Zero conicity

Up to 5 mm thickness

High aspect ratio

Roughness below the µm scale

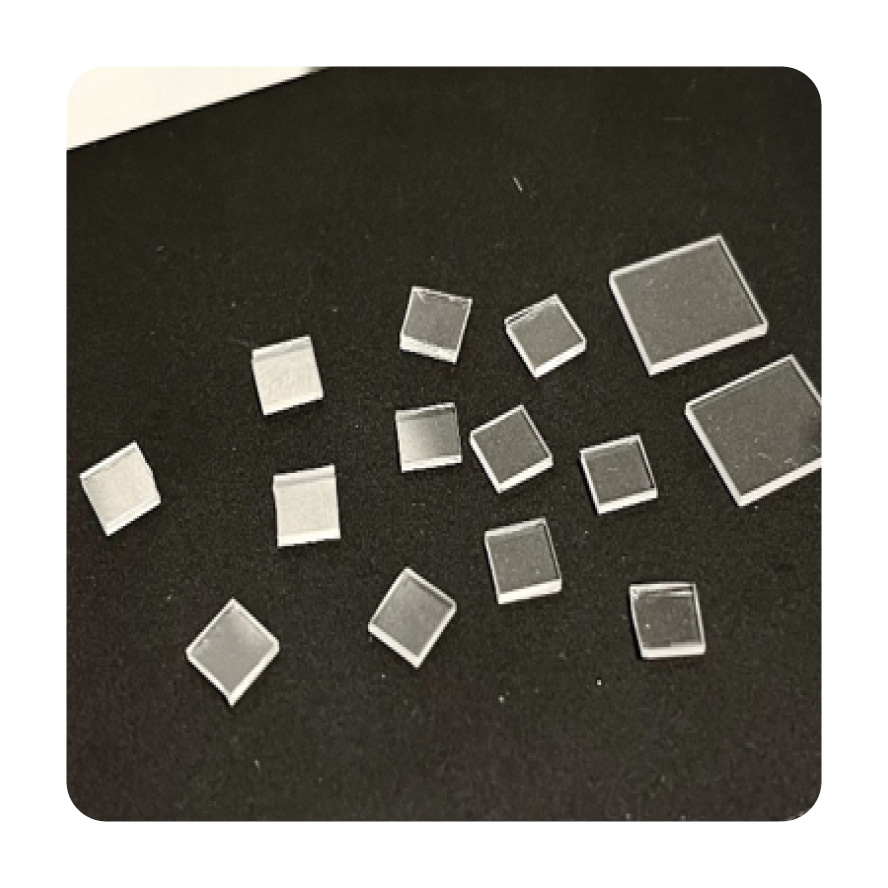

Cutting without material removal

-

No dust

Up to 5 mm thickness

Fast process > 100 mm / s

1 mm per pass

Roughness below 500 nm

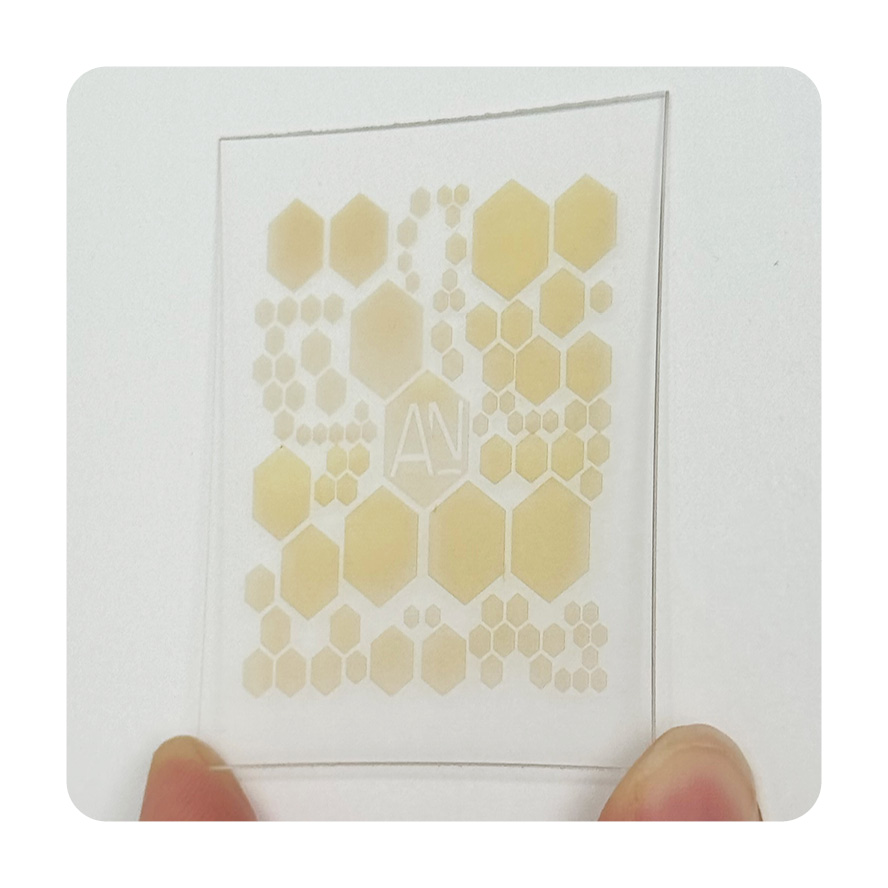

Change in refractive index within the volume

-

Localized and dust-free

1 µm precision in XYZ

Durable bulk processing

Unaltered surface finish

ALPhANOV adds value to your laser processing through advanced beam-shaping techniques such as DLIP (Direct Laser Interference Patterning), Bessel beams, and bottom-up approaches. Today, refractive index modification within the bulk of materials has become an industrially mature technology, fully mastered and deployed to serve your applications. These developments rely on a state-of-the-art laser platform, covering visible and ultraviolet wavelenghts, enabling the optimization and long-term differenciation of your laser processing.

Process sheet

Areas of application

- Watchmaking

- Photonics industry

- Display

- Aeronautics

- Space

- Defence

Publications

Associated products or services

-

Laser machining and micro-machining

Laser machining or laser micro-machining enables the production of very high-precision parts, with micrometer-scale tolerances. It is used for cutting, drilling, controlled engraving, selective ablation, and micro-turning operations. -

Surface engineering

Laser surface engineering or functionalization enables the creation of effects or the addition of new properties to all types of surfaces and materials, depending on the desired function.