News

A new 1000 W CW green laser at 515 nm available at ALPhANOV

Emitting green light, this new laser source will allow ALPhANOV to face the challenge of copper welding at high speed and optimal quality.

For more than 10 years, ALPhANOV has been working on the development of laser micro-machining processes. Cutting, etching, drilling, surface texturing, marking, as many processes feasible on different materials such as metals, transparent materials and composites.

High reflectivity and thermal conduction metals make various processes very sensitives. Among these metals, we can name copper and gold which were until now very complex to process because of technological limits. The absorptivity of copper and gold being very low at infrared wavelength, which is the most common wavelength used in the industry, delays the practice of Laser welding.

these metals, we can name copper and gold which were until now very complex to process because of technological limits. The absorptivity of copper and gold being very low at infrared wavelength, which is the most common wavelength used in the industry, delays the practice of Laser welding.

Overcoming these technological limits, thanks to many innovations in the photonic world offers unseen opportunities and new possibilities. The outbreak of high-performance green laser sources, more reliable than ever, enables processes producing low quality results with IR wavelength and thus not meeting the quality criterions of the industry.

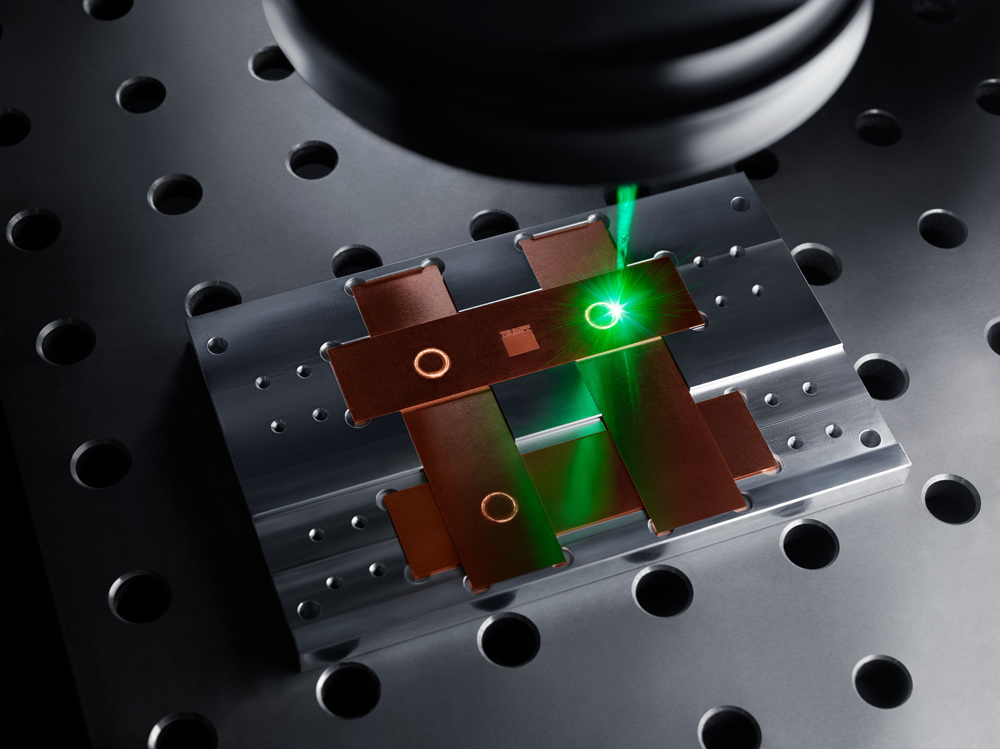

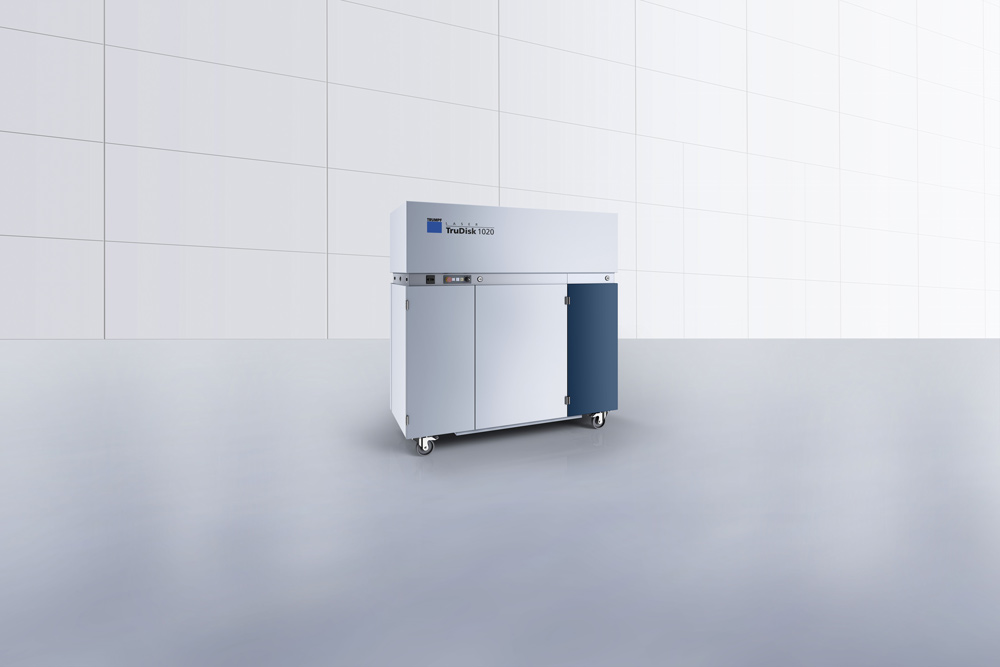

In this respect, ALPhANOV will have the opportunity to test a new green laser. The Trudisk 1020 from TRUMPF complete ALPhANOV’s collection of Laser sources. The Trusdisk is a 1000 W continuous wave laser emitting at a wavelength of 515 nm. Used with a PFO Scanner, the set up allows fast and precise on the fly processes.

The fields of applications are immense: the e-mobility domain is blooming due to the growing use of clean vehicles batteries; the micro and nano electronic domain, more and more miniaturized, is desirous of reaching higher level of performance and the luxury industry, which is more demanding than ever for laser processes have as a common feature the massive use of copper and gold.

The characteristics of the laser source and its affinity with non-ferrous metal make heat conduction welding and keyhole welding possible, keeping high-quality welding seam and significantly reducing spattering no matter the initial surface roughness of the sample The steadiness and replicability of the laser welding process of copper or gold allow high throughput and high precision, meeting Industry requirements.

More information

Do you have welding needs?

ALPhANOV's know-how and equipments are full available for yours projects!

👉 Request a study