Etching - Controlled ablation

Laser engraving is carried out by removing material layer by layer to obtain a 2D or 3D effect on all material types.

The characteristics of the etching - controlled ablation process:

Benefits

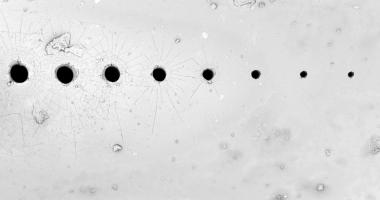

- Controlled ablation up to a few μm depth

- 3D part machining

Performance

- Roughness less than a few μm

- Tolerance of a few μm

- Accuracy of a few μm

Throughput

Variable depending on the material and the pulse duration: on the order of a few mm3.min-1

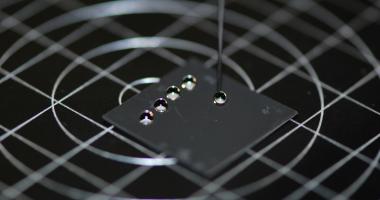

Laser workstation

- IR, green or UV laser

- Femtosecond to nanoscale pulse

- Scanning systems

Condition surface

Final surface roughness up to 0.5 μm

Process sheet

Areas of application

- Texturing of injection moulds

- Watchmaking

- Stamping tools

Publications

Associated products or services

-

Selective ablation

The use of a specific pulse duration and/or suitable wavelength(s) makes it possible to work in a condition where the surface layer ablation threshold is lower than the substrate’s. -

Machining of transparent materials

Cutting, welding, drilling and engraving of transparent materials with minimization of mechanical stress. Short or ultra-short pulse lasers allow transparent materials to be machined with or without removal of material and to modify their intra-volume physical properties. -

Laser drilling

Laser drilling makes it possible to create through or blind holes with variable shape and high aspect ratio, on all types of materials and thicknesses. -

Laser cutting

Laser cutting enables precision part production of all material types, even of transparent and hard materials such as SIC and diamond. -

Surface engineering

Laser texturing and surface functionalization make it possible to create effects or generate new properties on all surface types.