Single laser fault injection microscope - S-LMS

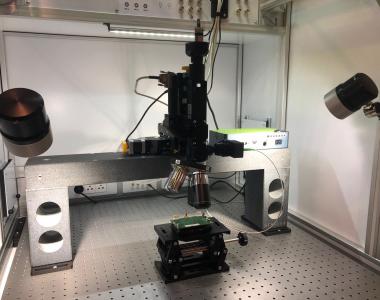

The S-LMS microscope station for laser fault injection is a high-precision platform for security evaluation of integrated circuits. It allows to focus the laser spot on the chip and scan the sample through the back side in order to evaluate the security levels of the electronic components.

Product reference: S-LMS

A 1-µm laser spot accuracy

The S-LMS laser fault injection platform integrates optics carefully designed by our teams to focus the laser source on the smallest possible spot sizes (1 µm) with the highest possible transmission (>90%). All the power of the PDM+ laser source (Pulse-On-Demand Module) is available on an extremely small circular spot, and can be focused on the active area of the component, through the silicon of the back side. Mounted on a high-resolution XYZ stage, the microscope system enables to scan the sample with a 50 nm.

Temporal precision of the laser

The PDM+ laser integrated into our fault injection microscope systems allows extremely precise timing control due to extremilly low jitter (<8 ps). This temporal control is essential to synchronize the laser injection with the operation of the circuit. This PDM laser can generate on demand pulses from 1 ns, up to continuous wave; from the single shot to a 250 MHz repetition rate.

Different PDM+ models can be integrated on the S-LMS bench:

- different wavelengths available for back side: 980 nm and/or 1064 nm,

- different powers (from 2 W to 10 W) depending on the sensitivity of your samples and the thickness of silicon,

- the new PDM HPP (High Pulse Performance) adapted for extremely short pulses (sub-ns).

A high-quality infrared vision

The laser fault injection S-LMS microscope has been specially designed to integrate a high-quality infrared lighting and vision. The high-resolution IR camera enables to obtain a good quality view of the paths of the chip through the back side even through several hundred micrometers of silicon. The laser spots can also be watched at the same time and easily placed or moved on the sample.

A wide range of lenses

ALPhANOV offers a wide range of high-performance lenses by focusing on optical quality, high numerical aperture for better resolution and high transmission. The S-LMS bench can integrate up to 4 lenses via a manual turret or 5 lenses via a motorized turret. You can choose the most appropriate magnifications, from the 50X lens offering the smallest spot sizes to the 2.5X lens for a global view of the sample or larger spot sizes for faster scans.

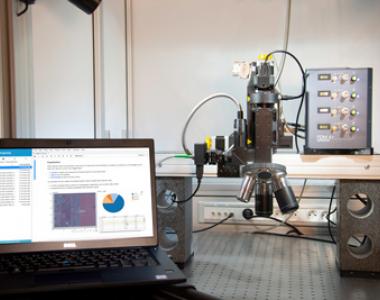

The driving software: strong partnership with eShard

All our benches can now be controlled via eshard’s esDynamic software. A powerful platform enables to use notebooks specially developed in Python, to integrate your own developments and to summarize and analyze your results. The esDynamic platform is also used for side-channel analysis.

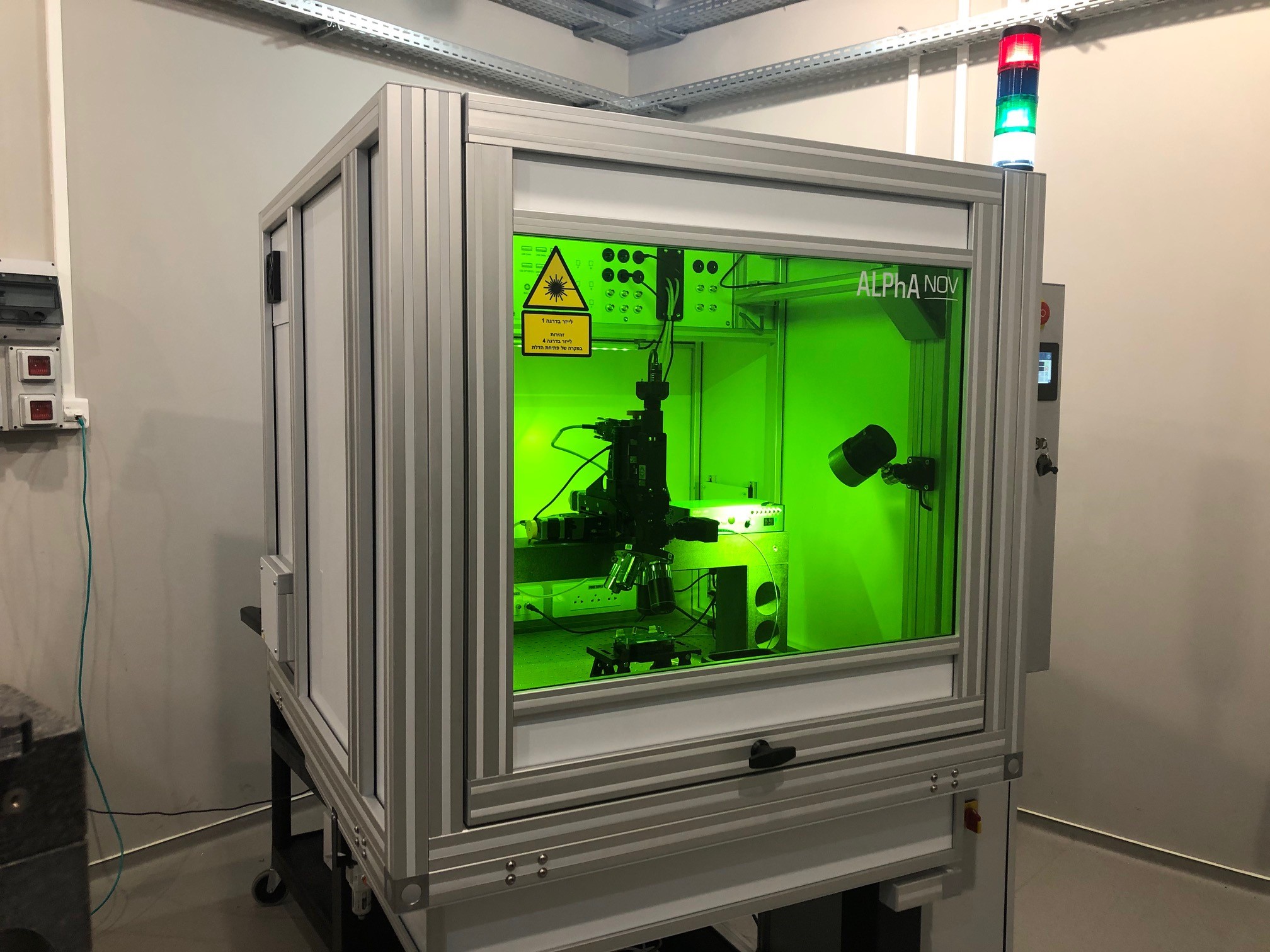

A turnkey and evolving fault injection bench

Experts in optics and lasers, ALPhANOV customize the laser fault injection systems to fit your projects, your budget and your skills. From made-to-measure bench to turnkey bench, we design the best solution for you, from a simple microscope to a completely automated machine integrating a CE-certified laser security enclosure mounted on an active optical table.

Every year, ALPhANOV brings developments and improvements for its laser fault injection benches. You can regularly update/upgrade your system with the latest technological advances in order to remain at the state of the art. As an example the functions of photoemission or thermal laser stimulation are now available on a S-LMS bench.

Product features

- Single-mode laser at 980 and/or 1064 nm

- Pulses sub-ns to continuous wave

- Temporal precision <8 ps

- Frequency up to 250 MHz

- >92% transmission

- Coaxial IR vision

- Can be controlled and driven by Python

Possible options

CE-certified laser security barrier

Photoemission kit

Laser path for thermal stimulation

esDynamic software platform

Applications

- Fault injection

- Photoemission

- Thermal stimulation

Associated products or services

-

Double laser fault injection microscope - D-LMS

The D-LMS microscope station for double laser fault injection is a platform allowing to focus and scan independently two laser spots for security evaluation of integrated circuits. Ideal for double spot injection processes, it offers all the spatial and temporal flexibility to analyze circuits through the back side. -

PDM laser sources - Pulse-on-demand Modules

PDM laser sources are specially designed for security evaluation of integrated circuits. Reliable and robust, these laser sources allow you to generate pulses on demand of less than 1 nanosecond, up to continuous with a timing precision of 8 ps and a spot size of 1 µm. -

Photoemission optical bench

When an integrated circuit is in operation, the zones requested by the routine naturally emit infrared photons via the rear panel. ALPhANOV’s photoemission optical bench allows you to capture and visualise these photonic emissions in order to obtain a precise view of the circuit activity. -

Thermal Laser Stimulation - TLS

The thermal laser stimulation bench is an optical microscope which enables to focus with precision, a PDM+ laser source (Pulse-on-Demand Module) at 1420 nm. Used through the back side of electronic components, the laser beam warms the sample locally and allows to extract and read out data in a memory according to the current consumption of the transistors. -

Tombak: Pulse Delay Generator

This pulse delay generator generates high frequency pulses, digital delays and bursts. It is an ideal synchronization and timing control instrument for electronics and lasers.